Lean Production Process for High-Quality Welded Tubes

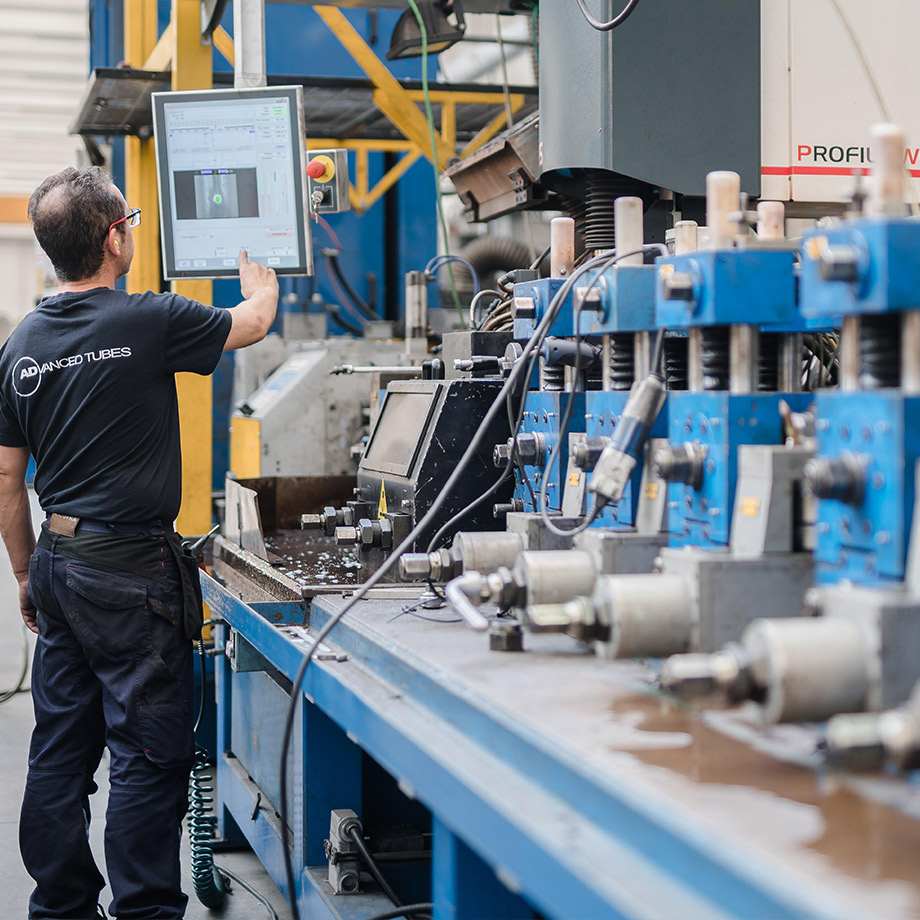

A.D. Tubi Inossidabili adopts an advanced Lean production process that ensures the efficient execution of all manufacturing operations. By minimizing manual handling during production, we achieve welded tubes with consistent quality while optimizing production times and quality control.

Cutting-Edge

Welding Technologies

Our welded tube production relies on two industry-leading technologies:

TIG Welding (GTAW) – Proven Technology

- Tungsten Inert Gas welding for excellent metallurgical quality

- Precise control of the welding process

- High repeatability and consistent quality

- Suitable for special materials and critical applications

Laser Welding – Advanced Technology

- Precision laser welding with short thermal cycles

- Reduced heat-affected zone for optimal properties

- Superior millimetric accuracy for certain special materials

- Ideal for thin-walled tubes and tight tolerances

Bright Annealing

All our welding lines are equipped with bright annealing furnaces, ensuring:

- Shiny surface finish with no oxidation

- Optimal mechanical properties of the material

- Maximized corrosion resistance

- Compliance with the strictest international standards

Technological Investments

and Continuous Training

We continuously invest in:

- Cutting-edge production technologies

- Automated quality control systems

- Certified specialist training for employees

- Research and development for ongoing innovation

These investments have driven the company’s remarkable growth and confirm the strong commitment to excellence in processes and products.

Product Range

Dimensions and Geometric Characteristics

Available Size Range:

- Diameter: from ø7 mm to ø76.2 mm – .281’’ to 3’’

- Wall thickness: from 0.4 mm to 4 mm – .016’’ to .154’’

- Fixed lengths: up to 30 meters – 100’

- Special shapes: round, oval, elliptical, rectangular, and custom shapes upon request

Special Configurations:

- Straight tubes for standard applications

- U-bent tubes for heat exchangers

- Finned tubes for optimized heat transfer

- Customized forms according to customer specifications

Materials

| EN | UNS | TP |

|---|---|---|

| 1.4301 | S30400 | TP304 |

| 1.4306 | TP304L | |

| 1.4307 | S30403 | TP304L |

| 1.4311 | S30453 | TP304LN |

| 1.4404 | S31600 | TP316 |

| 1.4404 | S31603 | TP316L |

| 1.4406 | S31653 | TP316LN |

| 1.4432 | TP316L | |

| 1.4435 | TP316L | |

| 1.4436 | TP316 | |

| 1.4438 | S31703 | TP317L |

| 1.4439 | S31726 | TP317LNM |

| S31700 | TP317 | |

| 1.4449 | TP317 | |

| 1.4550 | S34700 | TP347 |

| 1.4541 | S32100 | TP321 |

| 1.4571 | S31653 | TP316Ti |

| 1.4828 | TP309 | |

| 1.4833 | S30908 | TP309S |

| 1.4845 | S31008 | TP310S |

| 1.4878 | S32109 | TP321H |

| 1.4948 | S30409 | TP304H |

| 1.4835 | S30815 | 253MA® |

| S33400 | Alloy 840 |

| STANDARD |

|---|

| EN 10217/7 TC1 & TC2 |

| EN 10296-2 |

| EN10357 |

| DIN 11850 |

| AD 2000 W2 - W4- W10 |

| ASTM/ASME A/SA249 |

| ASTM A269 |

| ASTM A270 |

| ASTM A554 |

| ASTM A632 |

| ASTM A778 |

| ASTM/ASME B/SB674 |

| ASTM/ASME A/SA312 |

| ASTM/ASME A/SA688 |

| ASTM/ASME B/SB676 |

| EN | UNS | GRADE |

|---|---|---|

| 1.4529 | N08926 | 1925HMo® |

| N08367 | TP304L | |

| 1.4562 | N08031 | Alloy 31 |

| 1.4539 | N08904 | 904L |

| 1.4547 | S31254 | 254SMo® |

| STANDARD |

|---|

| EN 10217/7 TC1 & TC2 |

| EN 10296-2 |

| ASTM/ASME A/SA249 |

| ASTM A269 |

| ASTM A270 |

| ASTM/ASME A/SA312 |

| ASTM/ASME B/SB676 |

| AD 2000 W2 |

| ASTM A632 |

| ASTM/ASME B/SB674 |

| ASTM/ASME A/SA688 |

| ASTM/ASME B/SB674 |

| ASTM/ASME A/SA468 |

| EN | UNS | GRADE |

|---|---|---|

| 1.4362 | S32304 | DSS 2304 |

| 1.4162 | S32101 | DSS 2101 |

| S32003 | DSS 2003 | |

| 1.4410 | S32750 | DSS 2507 |

| 1.4501 | S32760 | SDX 100® |

| S82031 | FDX 27® | |

| 1.4462 | S31803 | DSS 2205 |

| 1.4462 | S32205 | DSS 2205 |

| STANDARD |

|---|

| EN 10217/7 TC1 & TC2 |

| ASTM/ASME A/SA789 |

| EN10357 |

| AD 2000 W2 |

| EN 10296-2 |

| ASTM A554 |

| ASTM/ASME A/SA790 |

| EN | UNS | TP |

|---|---|---|

| 1.4016 | S43000 | TP430 |

| 1.4509 | TP441 | |

| 1.4512 | TP409 | |

| 1.4521 | TP444 | |

| S43932 | TP439M | |

| 1.4510 | TP439M | |

| 1.4520 | TP430Ti | |

| S43035 | TP439 | |

| S41008 | TP410S |

| STANDARD |

|---|

| ASTM /ASME A/SA268 |

| ASTM/ASME A/SA249 |

| EN10357 |

| ASTM A/SA803 |

| EN 10296-2 |

| ASTM A554 |

| EN | UNS | GRADE |

|---|---|---|

| 2.4602 | N06022 | Alloy 22 |

| 2.4605 | N06059 | Alloy 59 |

| 2.4660 | N08020 | Alloy 20 |

| 2.4633 | N06025 | Alloy 25 |

| 1.4563 | N08028 | Alloy 28 |

| 1.4876 | N08800 | Alloy 800 |

| 2.4858 | N08825 | Alloy 825 |

| 2.4360 | N04400 | Alloy 400 |

| 2.4816 | N06600 | Alloy 600 |

| 2.4851 | N06601 | Alloy 601 |

| 2.4700 | N06601 | Alloy 2120 |

| 2.4675 | N06200 | Alloy C2000 |

| 2.4068 | N02201 | Alloy 201 |

| 2.4733 | N06230 | Alloy 230 |

| 2.4819 | N10276 | C-276 |

| 2.4856 | N06625 | Alloy 625 |

| STANDARD |

|---|

| ASTM/ASME B/SB515 |

| ASTM/ASME B/SB516 |

| ASTM/ASME B/SB626 |

| ASTM/ASME B/SB704 |

| ASTM B/SB751 |

| ASTM/ASME B/SB730 |

| ASTM/ASME B/SB468 |

| AD 2000 W2 |

| EN 10217/7 TC1 & TC2 |

| GRADE |

|---|

| 1-2-2H-7-7H-12-16-16H |

| STANDARD |

|---|

| ASTM/ASME B/SB338 |

| ISO18762 |

PED 2014/68/EU Annex I, Section 4.3 AD2000 W0 and EN764-5, Para. 4.2

Manufacturer approved by RINA, Lloyd’s Register, KR Register, DNV, Norsok M-650. Product compliance to EU Commission Regulation no. 2023/2006 on good manufacturing practices for materials and articles intended to come into contact with food (GMP).

ISO 9001

ISO 14001 / ISO 45001