Production

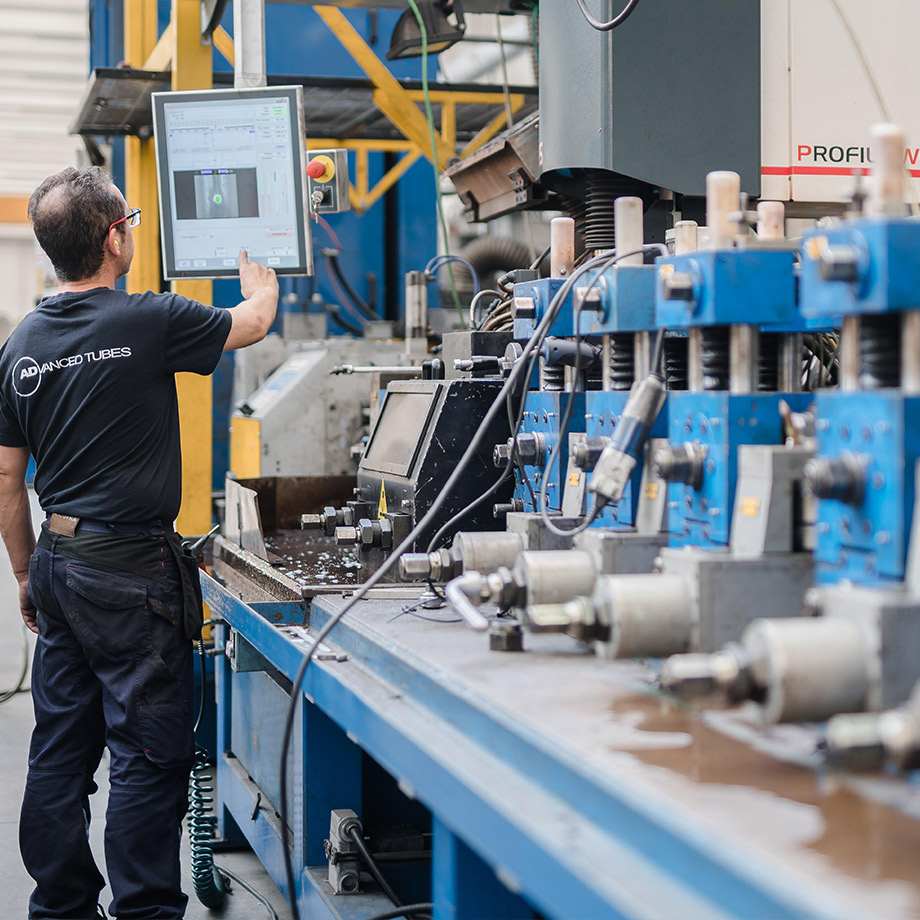

A.D. Tubi Inossidabili has developed a complete in-line lean manufacturing process that allows all operations to be performed very efficiently: minimal manual handling during production results in consistency of the products, time optimization and encompassive quality control.

We produce both GTAW(TIG) and laser welded tubes that offer very high quality products fitting all our customers’ needs.

Our constant investments in new production technology, quality and training of our employees have driven the tremendous growth of the company and certify the outstanding attention paid to our products.

TIG (Tungsten Inert Gas) welding is a consolidated technology that ensures an excellent metallurgical quality.

Laser welding is a newer technology with the advantage of a brief thermal cycle and limited heat affected zone.

All weld mills are equipped with bright annealing furnaces.

Product Range

Diameter: ø7mm to ø76,2mm / ø.281″ to ø3″

Wall thickness: 0,4mm to 4mm / .016″ to .154″

Fixed lengths: up to 30m / up to 100′

Round, oval, elliptical tubes, special shapes on request

U-tubes/Finned tubes

Materials

| EN | UNS | TP |

|---|---|---|

| 1.4301 | S30400 | TP304 |

| 1.4306 | TP304L | |

| 1.4307 | S30403 | TP304L |

| 1.4311 | S30453 | TP304LN |

| 1.4404 | S31600 | TP316 |

| 1.4404 | S31603 | TP316L |

| 1.4406 | S31653 | TP316LN |

| 1.4432 | TP316L | |

| 1.4435 | TP316L | |

| 1.4436 | TP316 | |

| 1.4438 | S31703 | TP317L |

| 1.4439 | S31726 | TP317LNM |

| S31700 | TP317 | |

| 1.4449 | TP317 | |

| 1.4550 | S34700 | TP347 |

| 1.4541 | S32100 | TP321 |

| 1.4571 | S31653 | TP316Ti |

| 1.4828 | TP309 | |

| 1.4833 | S30908 | TP309S |

| 1.4845 | S31008 | TP310S |

| 1.4878 | S32109 | TP321H |

| 1.4948 | S30409 | TP304H |

| 1.4835 | S30815 | 253MA® |

| S33400 | Alloy 840 |

| STANDARD |

|---|

| EN 10217/7 TC1 & TC2 |

| EN 10296-2 |

| EN10357 |

| DIN 11850 |

| AD 2000 W2 - W4- W10 |

| ASTM/ASME A/SA249 |

| ASTM A269 |

| ASTM A270 |

| ASTM A554 |

| ASTM A632 |

| ASTM A778 |

| ASTM/ASME B/SB674 |

| ASTM/ASME A/SA312 |

| ASTM/ASME A/SA688 |

| ASTM/ASME B/SB676 |

| EN | UNS | GRADE |

|---|---|---|

| 1.4529 | N08926 | 1925HMo® |

| N08367 | TP304L | |

| 1.4562 | N08031 | Alloy 31 |

| 1.4539 | N08904 | 904L |

| 1.4547 | S31254 | 254SMo® |

| STANDARD |

|---|

| EN 10217/7 TC1 & TC2 |

| EN 10296-2 |

| ASTM/ASME A/SA249 |

| ASTM A269 |

| ASTM A270 |

| ASTM/ASME A/SA312 |

| ASTM/ASME B/SB676 |

| AD 2000 W2 |

| ASTM A632 |

| ASTM/ASME B/SB674 |

| ASTM/ASME A/SA688 |

| ASTM/ASME B/SB674 |

| ASTM/ASME A/SA468 |

| EN | UNS | GRADE |

|---|---|---|

| 1.4362 | S32304 | DSS 2304 |

| 1.4162 | S32101 | DSS 2101 |

| S32003 | DSS 2003 | |

| 1.4410 | S32750 | DSS 2507 |

| 1.4501 | S32760 | SDX 100® |

| S82031 | FDX 27® | |

| 1.4462 | S31803 | DSS 2205 |

| 1.4462 | S32205 | DSS 2205 |

| STANDARD |

|---|

| EN 10217/7 TC1 & TC2 |

| ASTM/ASME A/SA789 |

| EN10357 |

| AD 2000 W2 |

| EN 10296-2 |

| ASTM A554 |

| ASTM/ASME A/SA790 |

| EN | UNS | TP |

|---|---|---|

| 1.4016 | S43000 | TP430 |

| 1.4509 | TP441 | |

| 1.4512 | TP409 | |

| 1.4521 | TP444 | |

| S43932 | TP439M | |

| 1.4510 | TP439M | |

| 1.4520 | TP430Ti | |

| S43035 | TP439 | |

| S41008 | TP410S |

| STANDARD |

|---|

| ASTM /ASME A/SA268 |

| ASTM/ASME A/SA249 |

| EN10357 |

| ASTM A/SA803 |

| EN 10296-2 |

| ASTM A554 |

| EN | UNS | GRADE |

|---|---|---|

| 2.4602 | N06022 | Alloy 22 |

| 2.4605 | N06059 | Alloy 59 |

| 2.4660 | N08020 | Alloy 20 |

| 2.4633 | N06025 | Alloy 25 |

| 1.4563 | N08028 | Alloy 28 |

| 1.4876 | N08800 | Alloy 800 |

| 2.4858 | N08825 | Alloy 825 |

| 2.4360 | N04400 | Alloy 400 |

| 2.4816 | N06600 | Alloy 600 |

| 2.4851 | N06601 | Alloy 601 |

| 2.4700 | N06601 | Alloy 2120 |

| 2.4675 | N06200 | Alloy C2000 |

| 2.4068 | N02201 | Alloy 201 |

| 2.4733 | N06230 | Alloy 230 |

| 2.4819 | N10276 | C-276 |

| 2.4856 | N06625 | Alloy 625 |

| STANDARD |

|---|

| ASTM/ASME B/SB515 |

| ASTM/ASME B/SB516 |

| ASTM/ASME B/SB626 |

| ASTM/ASME B/SB704 |

| ASTM B/SB751 |

| ASTM/ASME B/SB730 |

| ASTM/ASME B/SB468 |

| AD 2000 W2 |

| EN 10217/7 TC1 & TC2 |

| GRADE |

|---|

| 1-2-2H-7-7H-12-16-16H |

| STANDARD |

|---|

| ASTM/ASME B/SB338 |

| ISO18762 |

PED 2014/68/EU Annex I, Section 4.3 AD2000 W0 and EN764-5, Para. 4.2

Manufacturer approved by RINA, Lloyd’s Register, KR Register, DNV, Norsok M-650. Product compliance to EU Commission Regulation no. 2023/2006 on good manufacturing practices for materials and articles intended to come into contact with food (GMP).

ISO 9001

ISO 14001 / ISO 45001